The automated system of quality control in production allows you to monitor the most important processes, excluding the human factor. Thus, on any product line and at any time, the quality of products remains the same and meets the standards.

Lumos is a Rios robotic quality control system that selects products with defects in any production chain, is easy to manage and deploy, so it is currently actively used in many industries. It is suitable even for food industry enterprises.

Why do you Need Quality Control in Production?

Automation quality control has many advantages:

- High productivity;

- Compliance with quality standards;

- Increasing the level of production;

- Reduction of idle time on lines and the amount of waste.

In addition, the manufacturing quality control software has a convenient interface so that it is easy for the employee to navigate the management system and configure robotic solutions for the specific needs of the factory.

What are The Advantages of Workcell Lumos?

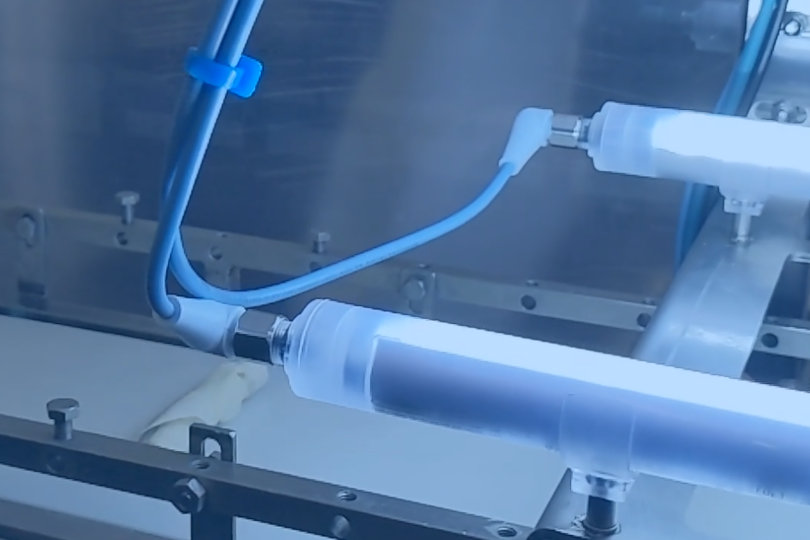

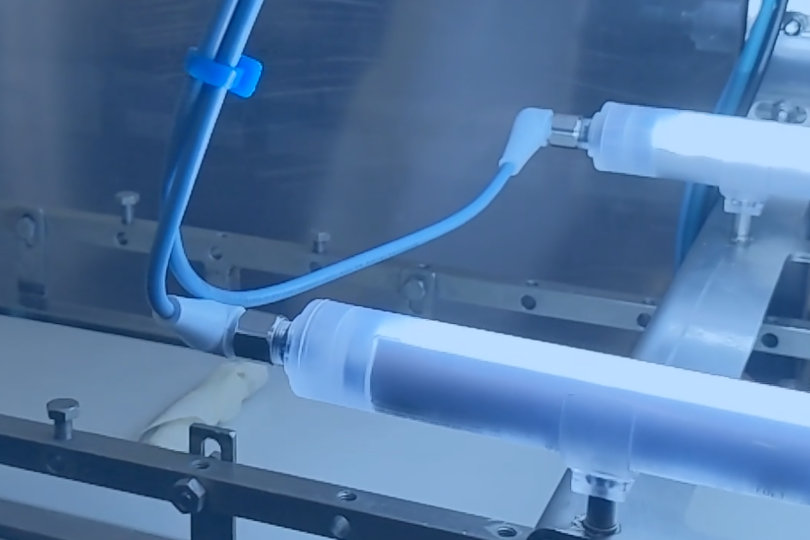

Lumos is a robotic quality control solution suitable for monitoring any production line. At the same time, the robotic system automatically transmits all the necessary data to the user in real time without any delays.

AI-vision, which is the basis of the quality control solution, checks and measures every corner of the product. The software collects and processes all the data, providing a detailed report. In the future, such data help to optimize processes and make finished products even better.

Technical Features of Lumos

The productivity of the Lumos robot from Rios is impressive: in a minute, the robot processes 100 units of products, detecting defects based on AI.

Lumos robotic quality control is integrated into both new and existing production lines. The system is flexible and easy to place, so it is quite convenient and profitable. Moreover, Lumos is used as a connecting line or can work with an output conveyor. The company can integrate a new control system at any stage: both before the start of the factory and when the factory is already in operation: the solution integrates with other technologies and is universal. Moreover, the system adapts to any size and type of product.

Keep in mind that Rios offers its systems and services as a RaaS, which means that you can customize your factory to your needs, and it will be affordable.