Starting a new business means you have a lot to coordinate. Marketing, product development, research into your target audience, and simply setting up your HR procedures and business structure can absorb all of your time, but there’s another vital element: planning your supply chain.

COVID-19 pushed supply chain management into the spotlight, especially during the early months of the pandemic, when ports closed, flights were canceled, ground freight was stuck in locked-down cities and factories closed their doors.

Thousands of businesses, from large retail corporations to small online sellers, were left without sufficient inventory, or watched stock stranded in their warehouses pass its literal or metaphorical ship-by date, unable to move it on for delivery or distribution.

A survey by the Institute for Supply Management (ISM) found that 75% of US businesses experienced disruptions due to the pandemic, and 44% had no plan to cope with it.

As we move on to 2021, no one could claim that supply chain logistics is a trivial matter. Advance planning is crucial if you’re to avoid these six supply chain pitfalls that lie in wait for new business owners.

1. Not Having Enough Data

You need reliable, real-time data about the progress of your goods, how they are being handled, and the conditions they are in. Fast, accurate data allows you to respond quickly to delays or clear up setbacks without letting your customers down. Over half of the ISM study’s respondents said that in February and March 2020, they struggled to get supply chain information from China, making it even harder for them to find out what happened to their orders so they could satisfy impatient customers.

It’s even more important if you’re shipping temperature-sensitive or fragile items that need careful handling and specific conditions. Consumers have little patience for orders that arrive damaged or looking different from their expectations. A cold chain temperature monitoring system that delivers real time data helps you ensure products arrive in perfect condition and haven’t been compromised.

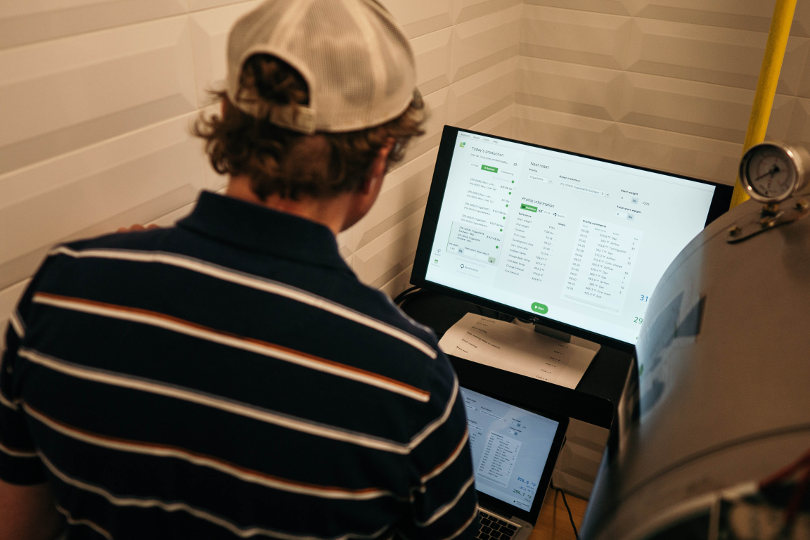

Of course, this requires a digitized supply chain analytics system. Tracking your shipments with an Excel spreadsheet manually updated every time you receive an email alert simply isn’t going to cut it, not even for small upstart businesses.

2. Tracking the Wrong KPIs

Setting the right KPIs puts you in position to measure the right metrics, so you can prioritize your efforts on the issues that have the most impact on your business. In turn, working with shrewdly chosen KPIs puts the onus on you to understand your customers’ biggest concerns, such as delivery turnaround lags, prices or item conditions upon arrival.

For example, your KPIs might focus on fulfilment times, which pushes you to prioritize the fastest, but more expensive, logistics provider. But if your customers are happy enough to wait another couple of days for their orders in exchange for free shipping, then you’d likely be better off working with a different shipping partner. Work out which KPIs are the most important for your target market, your product itself, and your business needs.

It’s also important to align KPIs across all your teams to optimize the entire supply chain. It’s no use saving money by combining orders into fewer, larger shipments, if it means you have to hire extra warehouse staff to cope with the large product volume.

3. Forgetting to Plan for the Unexpected

If there’s one lesson we should all have learned from 2020, it’s that resilience is crucial. Natural disasters, strikes, political upheavals, and more can develop in the blink of an eye and throw a monkey wrench in your supply chain works, so don’t build out a supply chain that’s so rigid that the slightest disruption or delay throws off the entire network.

You also need to allow for future business growth. When your company scales, can your supply chain scale with you? Everything might be running smoothly with 40 orders per day, but what about when you have to handle 80, 150, or more?

You need to find that sweet spot between keeping it lean, and wasting money on inefficient and unnecessary alternative partners.

4. Building a Siloed Network

Siloed teams create a fragmented supply chain with limited visibility. They are more common in large, complex and extended supply chains, but the decisions you make at the beginnings of your business determine whether your teams and tools can work together smoothly, or exist in isolation.

When data is siloed on separate platforms, you’ll be unable to spot opportunities to cut costs or identify the source of disruptions.

Lay the groundwork now for a unified and fully visible supply chain by ensuring that data from all your logistics, warehousing, suppliers and other partners is combined in a single platform for analysis. Then make sure that you establish easy communication methods for every entity.

5. Putting Price Above All

You want to spend as little as possible on supply chain management, but you still want excellence in service and execution.

If you only look for the cheapest partners, you’re liable to end up compromising on other issues like reliability, speed or levels of quality assurance transparency. Your logistics partners are fundamental to your business success, so be willing to invest a little more financially in a partner that will always have your back.

The business relationships in your supply chain need to deliver value, qualitative as well as quantitative.

6. Overlooking Security Controls

Ignoring or sidelining security concerns is asking for trouble. Data privacy regulations are rising, and a data breach can bring a hefty fine as well as serious damage to your business reputation.

Assure yourself that all your logistics providers, vendors and suppliers comply with security requirements and data privacy standards.

It’s equally important to protect your physical product. Use logistics monitoring tools that alert you if someone tries to interfere with the packaging, and make sure to place seals and tamper-proof locks on containers, so that you’ll be fully aware of any attempts to pilfer or tinker with your merchandise.

Supply Chain Management Doesn’t Have to Be a Minefield

Supply chain management is one of the many vital elements to a successful business, no matter what your product. By paying attention to data availability, KPI optimization and security issues, avoiding silos, planning for all contingencies and considering the entire relationship with each partner, new business owners can avoid the most common supply chain pitfalls and set themselves on the path to success.