Entrepreneurs and established retailers are developing their own private label, direct-to-consumer products for ecommerce. But most of these DTC sellers don’t plan to manufacture those items in their own facilities with their own workforce, tools, and materials. Rather these businesses need a manufacturing partner.

Identifying a supplier, which may be located thousands of miles away in another country, is no small task. But it is not unique. Many businesses have done it successfully.

Competitor’s Suppliers

Whether a competitor is a massive company such as Apple or a small business selling skateboards, there is probably an analysis tool or an important document somewhere showing where your competitor has its products manufactured.

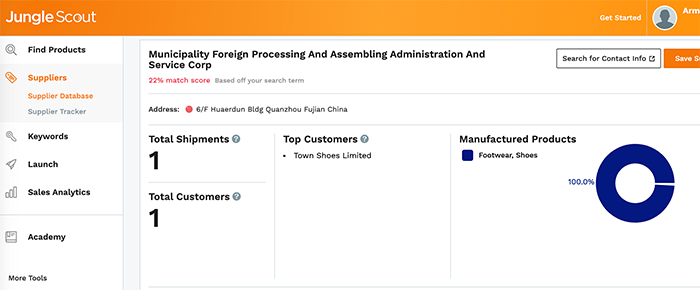

I recently spoke with Greg Mercer, CEO of Jungle Scout, an Amazon and ecommerce analysis tool. He described his company’s new supplier identification platform.

“We released something really cool about a half a year ago…it is a platform to find suppliers, but the data that we use for it is data that we get from the government organization that is in charge of customs and inbound shipments that are being imported into the U.S.”

“So through the Freedom of Information Act in the U.S. you can get access to government data, and we were able to do that.”

The Jungle Scout supplier tool lets users look up products, such as skateboarding shoes, of competitors.

“What’s cool about this is we essentially have all of the data from all imports coming into the U.S. When I say data, I am talking about who is importing it…who manufactured or created the goods, and some other information like quantities and weights… But the reason this is so powerful… [is that] you can see what factories different companies are using to manufacture their goods.”

When you know who makes your competitor’s widget, it may be easy to go to the factory and ask for something similar. You might even request a few improvements based on customer reviews of the competitor’s item.

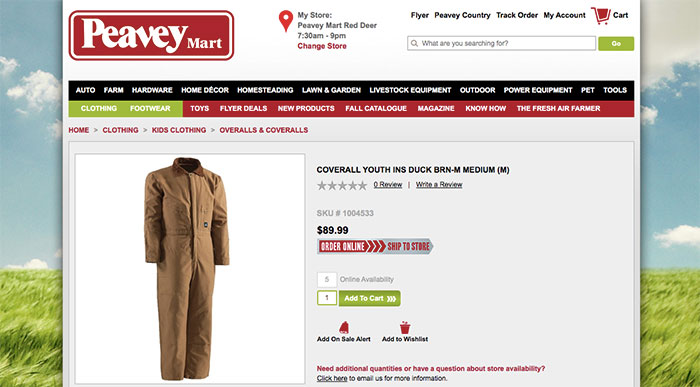

Some in the industry believe this is what Canadian retailer Peavey Mart did for its private label, duck cloth jackets and overalls. The products’ design and fabric are very similar to Carhartt jackets and overalls.

Peavey Marts duck cloth overalls may be manufactured by the same factory as Carhartt, a prominent brand.

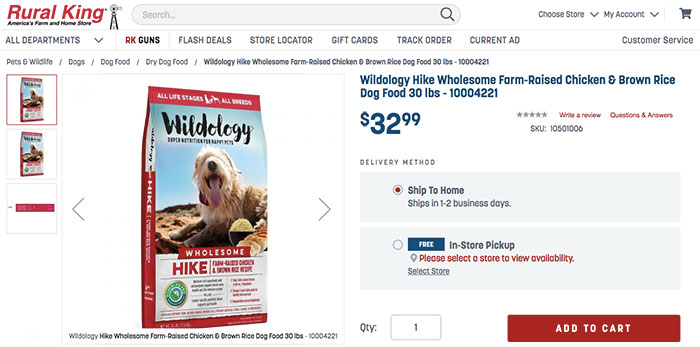

You might even take this a step further and learn if your competitor would be willing to manufacture for you, too. Mid-states Distributing Company, a retail membership organization representing 38 farm and ranch chains in the United States and Canada, recently launched a private label pet food brand, Wildology.

Rural King, a successful farm and ranch chain, is a member of Mid-states Distribution Company. Rural King sells the Mid-states brand Wildology, which is manufactured by a competitor.

At the time of writing, Wildology is manufactured by Schell & Kampeter, Inc., doing business as Diamond Pet Foods. Diamond, a competitor to Wildology, manufactures dog and cat food for several brands.

Try to discover who is manufacturing one of the leading brands in the market and ask that company to make your products, too.

Directories

Supplier directories are another option for identifying potential manufacturing partners.

One of the best-known directories in the United States is Thomas Register and its Thomasnet website. This directory lists more than 500,000 suppliers. It describes the items those suppliers make and the services they provide.

Thomas Registry can help identify a supplier, including U.S.-based manufacturers.

You could also try Global Sources, which has a similar directory of worldwide suppliers. It is especially good at identifying component manufacturers — makers of consumer electronics.

Global Sources is another excellent directory, especially for electronics.

And don’t forget Alibaba. It lists ready-made products to order and resell almost immediately. It can connect your business to China-based manufacturers, too.

Alibaba is a popular site for finding ready-made products or China-based manufacturers willing to work with brands of all sizes.

Regardless of the directory, get references and samples to ensure your potential manufacturing partner will produce a quality product.

“If you talk to 1,000 sellers and said ‘hey, tell me a horror story about importing products,’ most of them would be around the quality of the goods,” Jungle Scout’s Mercer said. “Because a lot of times people will shop around [for a manufacturing partner] on price. But they don’t have a great way to gauge the quality of the product.”

The First Step

Finding a manufacturer takes legwork, whether you use a tool such as Jungle Scout or manually search for suppliers on Thomasnet, Global Sources, and Alibaba.

Thus identifying potential partners is only the first step. You will need to vet them, and they may want to vet you.

Moreover, you will likely go through a detailed and sometimes lengthy product design process, identifying, say, the product’s Pantone color code and the thickness of the cardboard to package it.